Inventory management has always been a high-stakes balancing act. Stock too much, and you tie up capital in unused goods. Stock too little, and you risk stockouts and lost sales. Today, thanks to the power of predictive analytics, third-party logistics (3PL) providers like 3Gistix are transforming this balancing act into a strategic advantage.

By using big data, AI, and machine learning to forecast demand with precision, predictive analytics enables 3PLs to help their clients make smarter inventory decisions—driving efficiency, lowering costs, and enhancing customer satisfaction.

What is Predictive Analytics in Inventory Management?

Predictive analytics uses historical data, real-time inputs, and machine learning algorithms to forecast future inventory needs. These forecasts help 3PL providers determine:

- Optimal stock levels

- Reorder points

- Demand surges and seasonal trends

- Inventory turnover rates

For logistics companies like 3Gistix, integrating predictive analytics tools means transforming reactive inventory systems into proactive, intelligent networks.

Analytics and Industry Statistics

According to Allied Market Research, the global predictive analytics market is expected to reach $41.5 billion by 2028, growing at a CAGR of 21.9%.

A report by McKinsey & Company found that predictive analytics in supply chain operations can reduce forecasting errors by up to 50%, leading to a 20-30% reduction in inventory costs.

Gartner estimates that organizations using advanced analytics experience a 15% increase in perfect order rates.

Internal case studies from 3Gistix reveal that clients saw a 25% reduction in overstock costs and a 20% improvement in order fulfillment speed after implementing predictive inventory strategies.

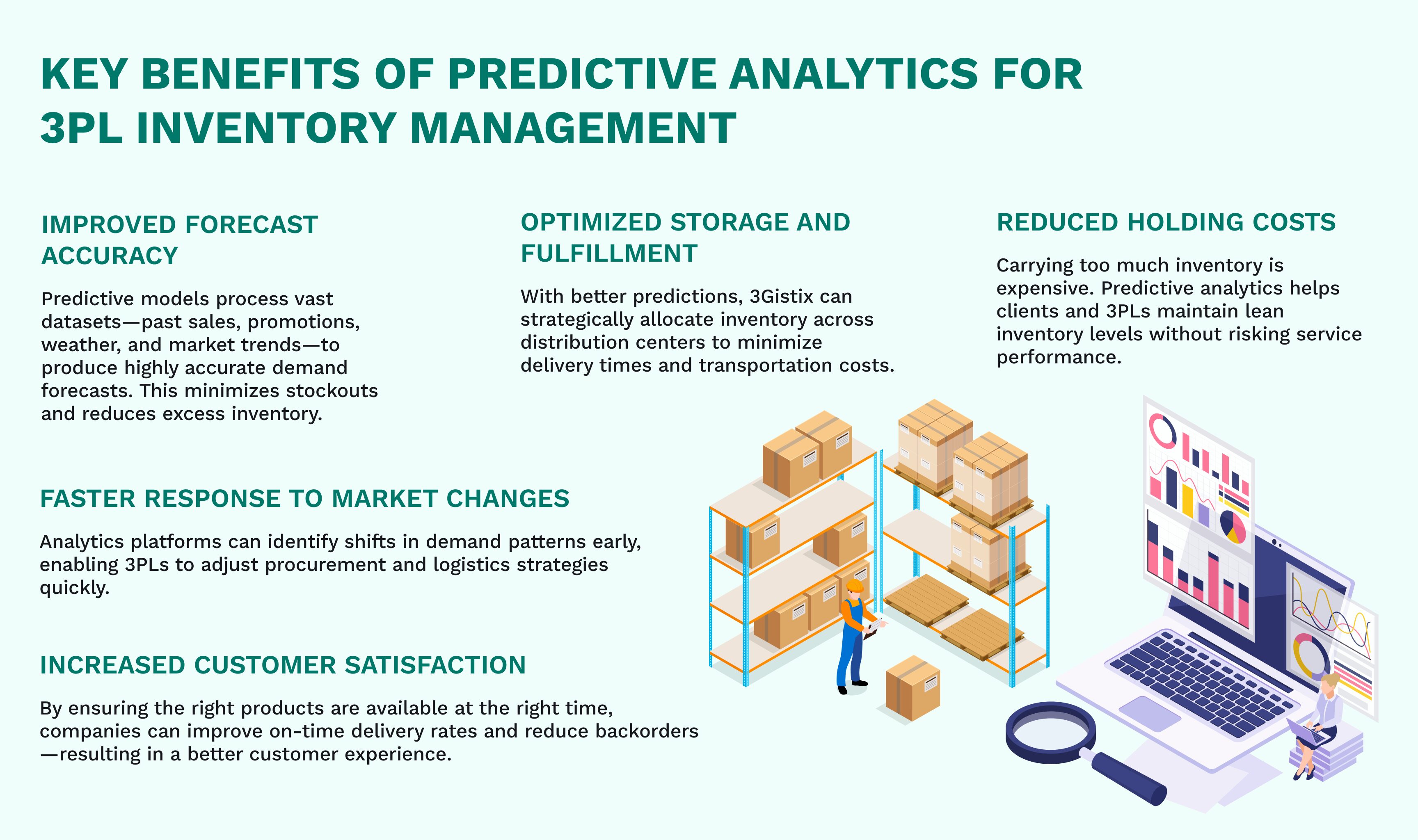

Key Benefits of Predictive Analytics for 3PL Inventory Management

Improved Forecast Accuracy

Predictive models process vast datasets—past sales, promotions, weather, and market trends—to produce highly accurate demand forecasts. This minimizes stockouts and reduces excess inventory.

Optimized Storage and Fulfillment

With better predictions, 3Gistix can strategically allocate inventory across distribution centers to minimize delivery times and transportation costs.

Reduced Holding Costs

Carrying too much inventory is expensive. Predictive analytics helps clients and 3PLs maintain lean inventory levels without risking service performance.

Faster Response to Market Changes

Analytics platforms can identify shifts in demand patterns early, enabling 3PLs to adjust procurement and logistics strategies quickly.

Increased Customer Satisfaction

By ensuring the right products are available at the right time, companies can improve on-time delivery rates and reduce backorders—resulting in a better customer experience.

How 3Gistix Leverages Predictive Analytics

As a data-driven logistics provider, 3Gistix integrates predictive analytics into every stage of the inventory management cycle. This includes:

- Using AI to predict SKU demand at the zip-code level

- Integrating client sales data with warehouse management systems (WMS)

- Applying machine learning models to optimize reorder points

- Analyzing lead times and vendor reliability to enhance supply chain agility

Through these initiatives, 3Gistix helps clients reduce waste, boost efficiency, and stay ahead in competitive markets.

Conclusion

In a world of rapid shifts in consumer behavior, global disruptions, and rising fulfillment expectations, predictive analytics is no longer optional—it’s essential. 3PLs like 3Gistix that invest in advanced analytics are delivering more than logistics—they’re delivering strategic foresight.

By transforming raw data into actionable insights, predictive analytics is rewriting the rules of inventory management, helping businesses become leaner, smarter, and more responsive. The future of logistics isn’t just fast—it’s predictive.

Reference

- Acropolium. Why Use Predictive Analytics in Supply Chains? Advantages, Use Cases & Solutions

- Extensiv. Supply Chain Predictive Analytics Explained

- Infosys BPM. How data analytics is delivering a competitive edge to 3PL service providers

- Overflo Warehouse. The Role of Predictive Analytics in Demand Forecasting for Logistics